Current markets for the development of deep water and other prospects can be high. Additional costs due to retrofitting, sample acquisition, and analysis errors can skyrocket into the billions, causing projects to go under or be severely compromised. In response to these delicate concerns, a new method of measurement and analysis, Downhole Fluid Analysis (DFA), has been developed. This new process improves efficiency while simultaneously preempting errors and sampling inaccuracies.

Hydrocarbon compositional analysis with openhole wireline logging is a large and often uncertain prospect within the oil industry. Current technological processes have been unable to reduce the uncertainties related to hydrocarbon fluids and the subsurface. DFA seeks to reduce and eliminate these concerns by providing real-time fluid analysis for the components of fluid compositional grading and compartmentalization.

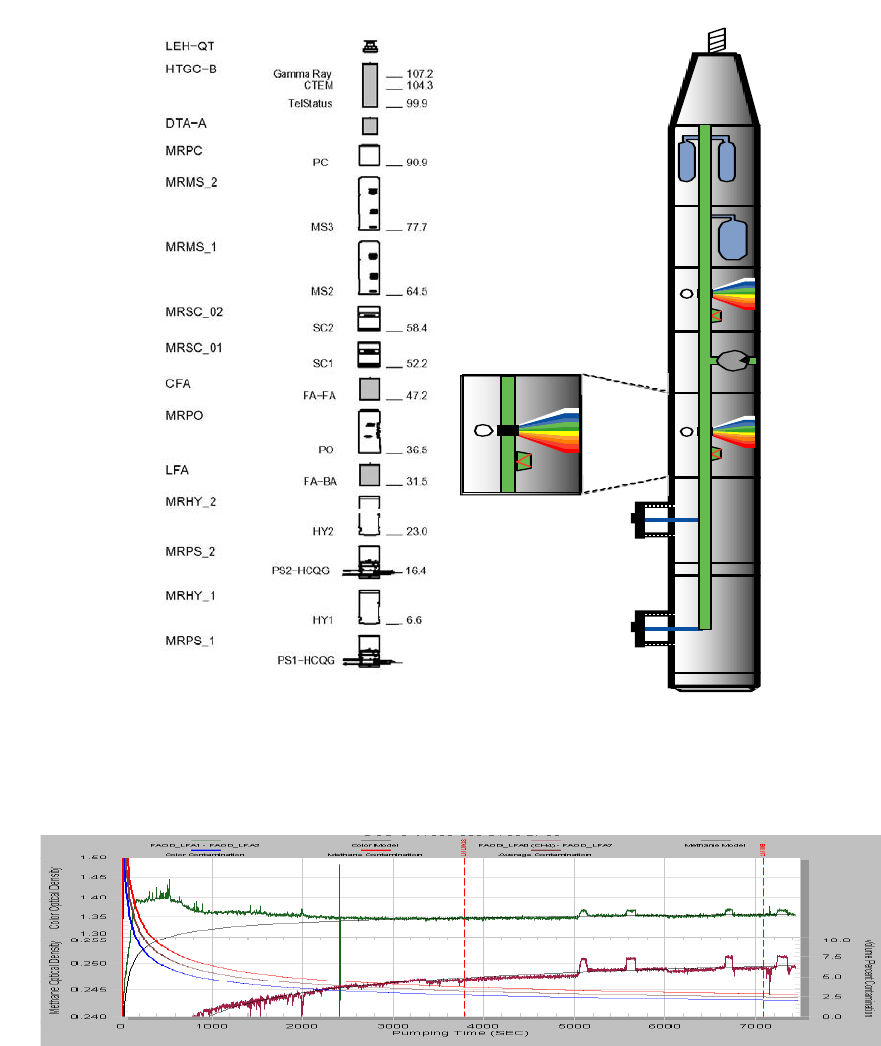

Compositional grading includes physical origins like gravity, biodegrading, leaky seals, and thermal gradients and cannot be modeled appropriately due to convective mixing which significantly alters compositional grading. DFA corrects this by picking out important and distinct samples for complete lab analysis. Furthermore, DFA remedies compartmentalization errors from flow rates and pressure maintenance by identifying over the analysis of pressure gradients alone to identify higher-density fluids in the oil column. Hydrocarbons included in the collection were CH4, hydrocarbon gases (C2-C5) and Hydrocarbon liquids (C6+) based on vibration modes of molecules.

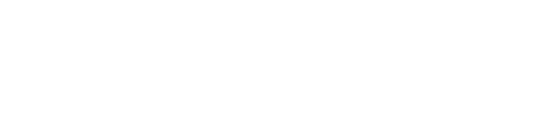

Combining this robust knowledge dramatically improves all sampling capabilities. This also reduces the non representative sampling, eliminates contamination of mud filtrate/other filtrates, and improves the high rate of errors leading to costly solutions. DFA data collection has been recognized to help with gas-oil (GOR) parameters, the cost of drill stem tests (DST) and the oil-based mud filtrate (OBM) by using DFA in the modular formation dynamic tester. Consequences of continued error are too great to ignore and too unsuccessful to be considered in regular business affairs.