Casing Inspection Specialists

Empire Wireline Special Services

- Empire Special Services Capabilities provide our clients with the most technology available for trip in the hole

- Ability to run MFC casing inspections & cement bond log simultaneously

- Ability to run MFC and electromagnetic thickness tool in the same run

- Ability to run all logging tools in combo

Now offering combinability for memory services.

Empire Wireline is the only independent company able to complete a caliper, thickness, and CBL in one trip in the hole!

We have capability to run all logging tools in combo.

Empire Special Services was formed to fill a void in the casing inspection market. Our personnel has over 60 years combined experience and are backed by the most technologically advanced casing inspection hardware and software in the industry.

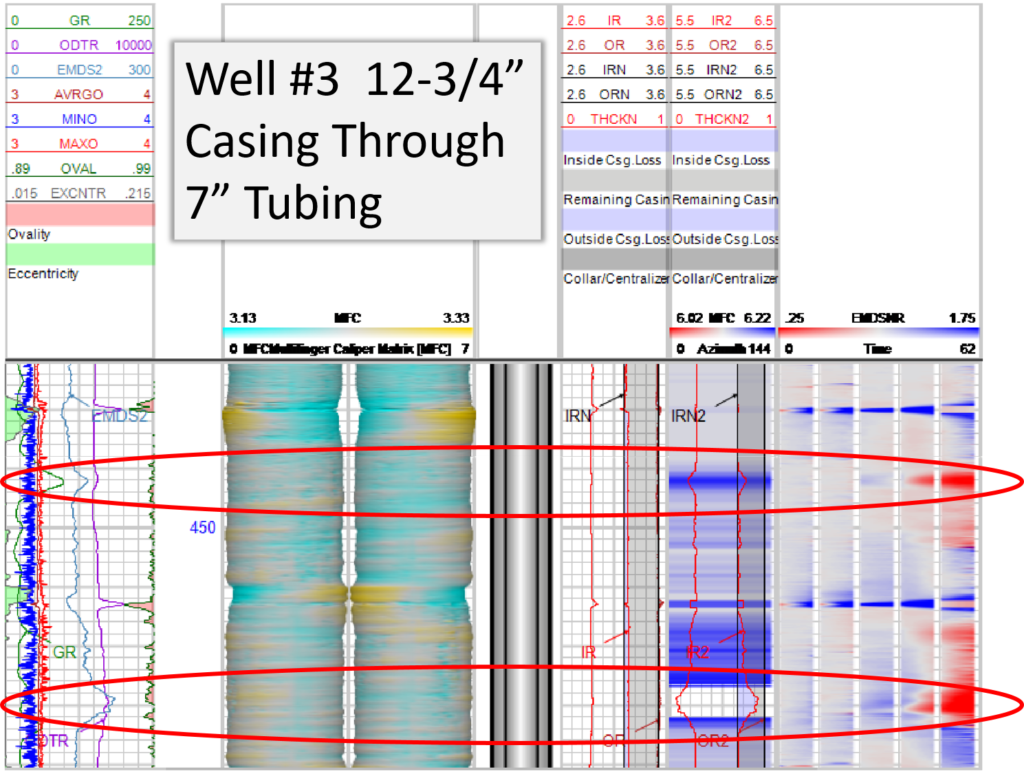

Empire is currently the only company operating in North America with the capability to provide our customers a full casing inspection survey by means of a point to point internal reading via a multi finger caliper (MFC), and an external corrosion assessment by means of our electromagnetic thickness tool (EMT).

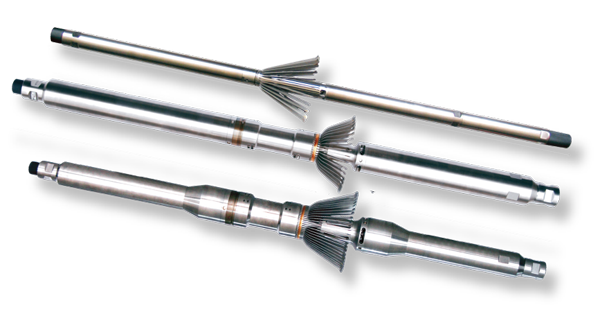

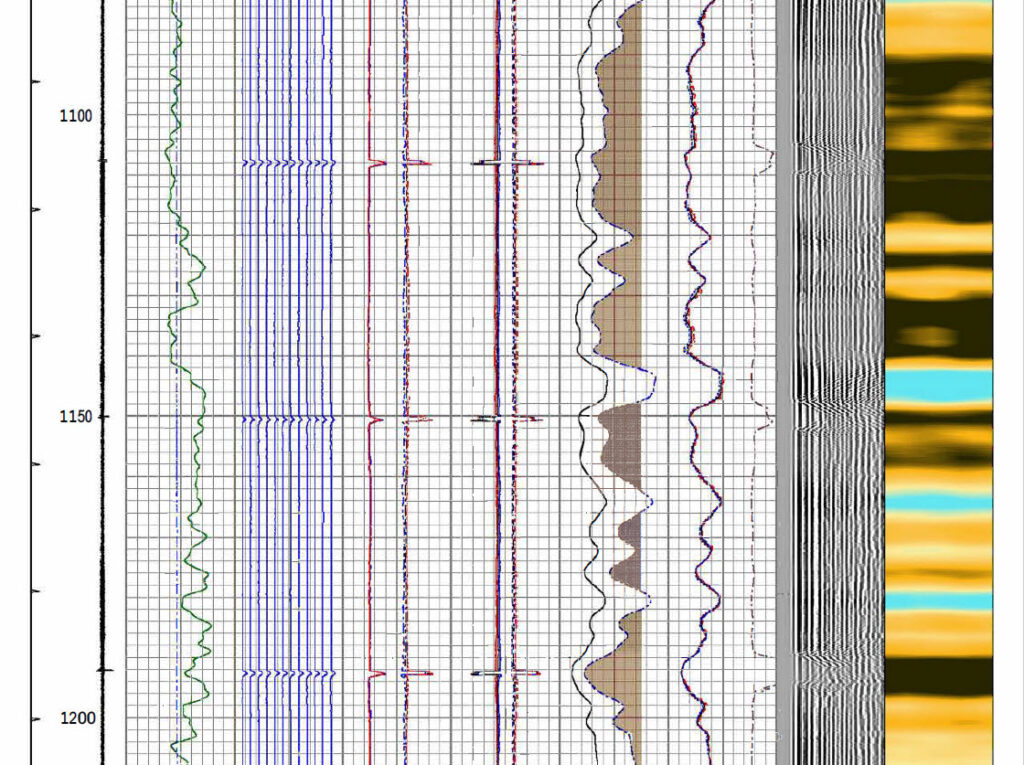

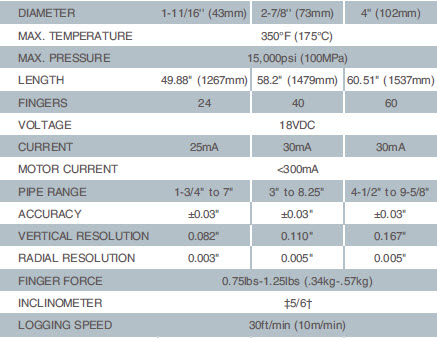

Multi-Finger Caliper

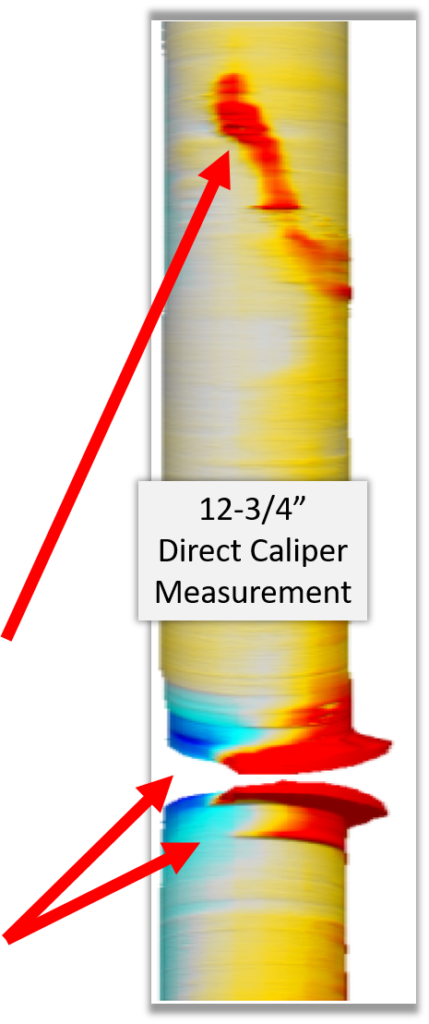

The Multi-Finger Caliper (MFC) has 24 to 60 high resolution calipers which measures the internal radii of the wellbore tubing and casing. Accurate measurements can be made in tubular sizes from 1.75 inches to 20 inches in diameter.

The MFC uses a series of “contactless” displacement sensors and a corresponding number of measurement fingers. When moving along the inner casing wall, the radial displacement will be changed into an axial displacement of the sensor, which is then processed, coded, and transferred to surface system where the image of the casing will be obtained.

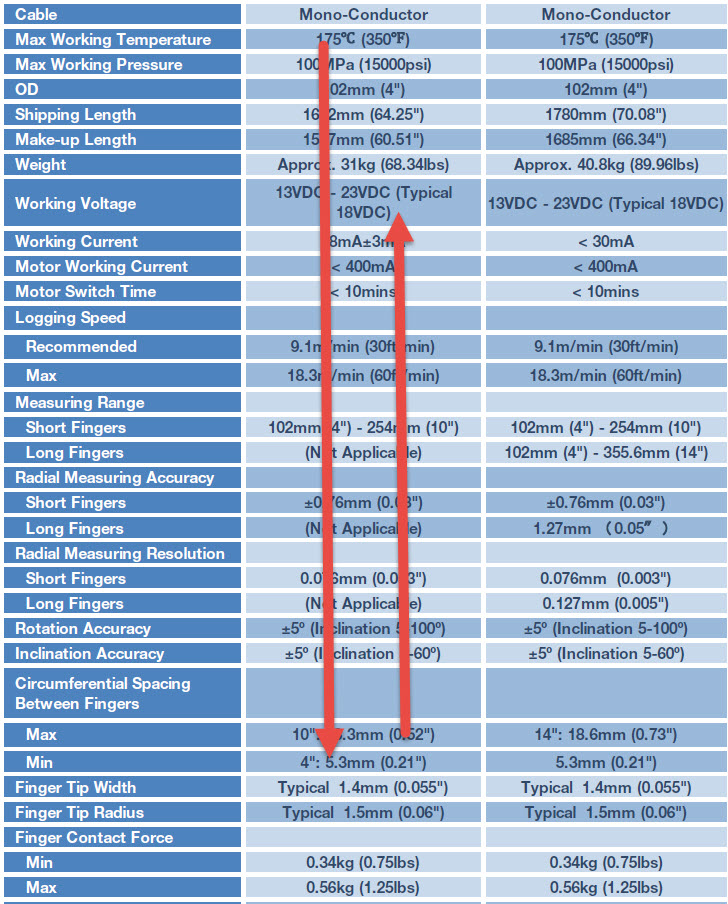

Multi-Finder Imaging Tool (60 Finger)

Overview

The Multi-Finger Imaging Tool (60-finger) has been designed to accurately measure

the inner diameter of casing and present the corrosion and scale deposition. The

sensing section consists of 60 dispalcement sensors, which are uniformlly distributed on the outer circumference, with each sensor able to measure the slightest variation in diameter. The tool also includes an inclination sensor and a rotation sensor.

The interpretation software is available for presenting the actual condition of the inner wall in a three-diemnsional view, and the engineering data of casing are calculated and recorded.

Applications

- Corrosion assessment

- Deformation evaluation

- Perforation mapping

- Well construction

- determination

- Accurate location of holes or anomalies

Features

- Wide range of pipe sizes measurable

- Ease of finger replacement

- SRO/memory modes

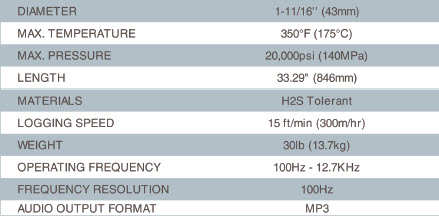

Specifications

Electromagnetic Casing Inspection Suite

Our EMT has the capability of providing the client a true corrosion assessment without having the influence of another, outer tubing string in the hole. In addition, our EMT can provide the client an assessment of the outer casing as well as the inner casing during the same trip in the hole. The following descriptions are just a sample of our tools and capabilities.

Electromagnetic Tool Specifications:

Electromagnetic Thickness Tool - Scanning (EMT-S)

The Electromagnetic Thickness Tool – Scanning (EMT-S) is designed to detect the damage of tubulars by calculating the remaining wall thickness and corrosion extent. By measuring the phase shift of an induced electromagnetic field, it can accurately indicate the column structure and location of other objects in concentric pipe. High resolution and fast sampling enable EMT-S to scan tubular geometry to provide positional location of nonconformities.

Applications

- Measure the remaining wall thickness of concentric casing in one run

- Determination of the type(s) of damage: pits, penetrations, cracks in transverse or longitudinal plane

- Determination of inner casing penetration

- Locating inner and outer collars in concentric casing

- Wellbore temperature logging

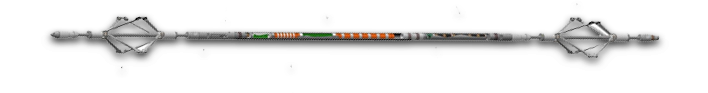

Electromagnetic Thickness Tool - Radial (EMT-R)

The Electromagnetic Thickness Tool – Radial (EMT-R) is designed to detect the damage of tubulars by calculating the remaining wall thickness and corrosion extent. Twelve bowspring arms contain sensors that measure residual thickness based on the remote field eddy current principle.

Processed data can be combined with caliper in order to generate detailed interpretation of wellbore condition along with 3D image.

Applications

- Measure the remaining wall thickness of casing

- Determination of the types of damage: pits, penetrations, cracks or transverse or longitudinal plane

- Sectored sensors allow localized identification of damage

- Inner and Outer wall damage identification

- Casing collar identification

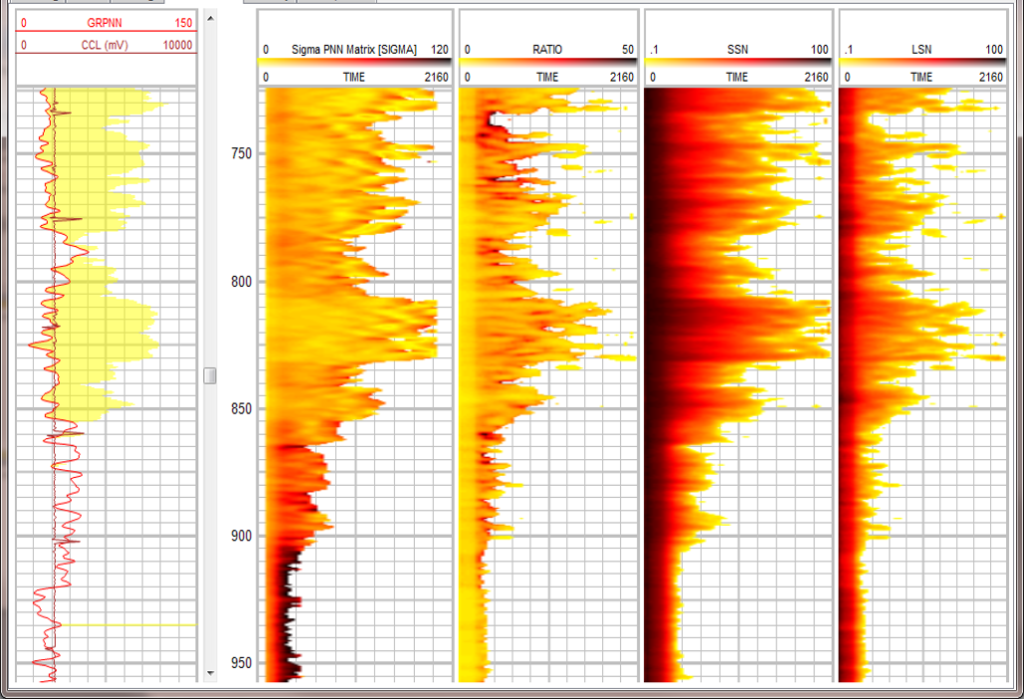

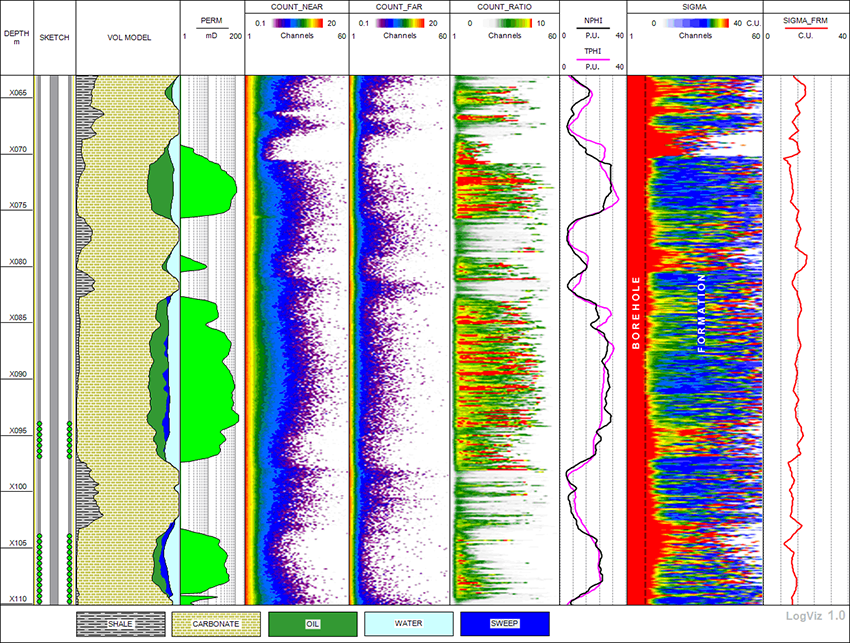

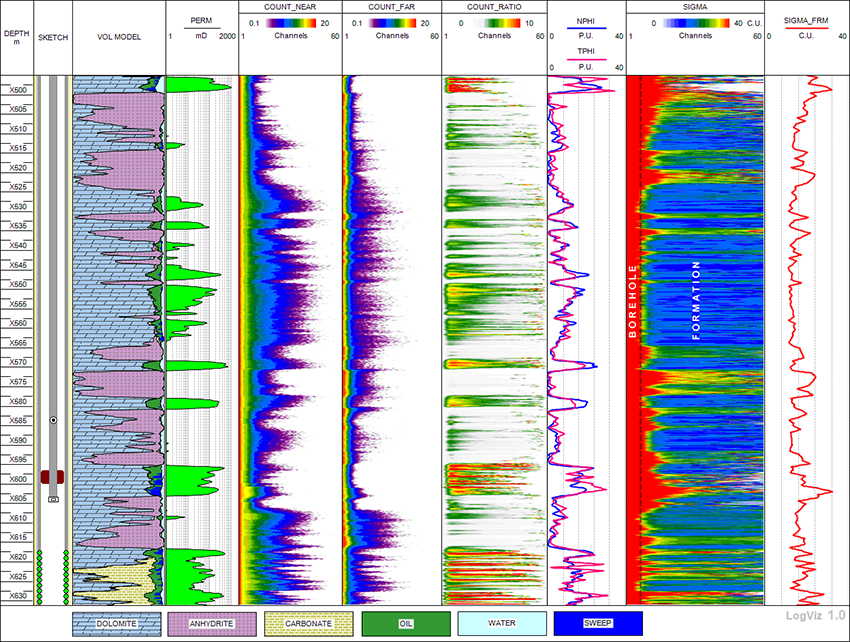

Pulsed Neutron Option

Pulsed Neutron Neutron PNN

PULSE NEUTRON NEUTRON TOOL (PNN) measures sigma, the ability of material to capture thermal Neutrons, in capture units (c.u.).

PNN directly counts the thermal neutrons reaching the detectors after their interaction with the surrounding formation. The usual inference by common thermal decay tools that count Gamma rays where High-counts means high-sigma-Values changes by the PNN tool into High-counts means low-sigma-Values. It has the significance of obtaining statistical uncertainties reduction for low sigma values.

This sole measuring approach allows better differentiation in environments of low sigma values, which is the case when fresh water, oil and/or gas are present in the pore spaces, overcoming by this way, the low salinity formation water problem which appears as a limitation factor of standard thermal Decay time tools; additionally, Neutron readings are less affected by Neutron activation, hence, logging of time-driven stop-Checks in area of interest helps reduce the statistical uncertainties of readings at any de-sired depth spot.

All of this makes PNN tool, in conjunction with our PNN processing and analysis software, a competitive behind-casing formation evaluation tool for high to moderate water salinity formations and the ultimate thermal decay tool for evaluation of lower salinity and lower porosity formations.

Applications

- Water saturation behind casing, porosity

- Remaining Hydrocarbon reserves estimation

- Oil-water

- Gas-water and gas-oil contacts location

Operation

The formation is bombarded with pulses of high-energy neutrons (14 MeV) generated by the tool. Neutrons interact with the surrounding atoms and during the lapse of time between high-energy neutron pulses.

The thermal neutron population that reaches the Neutron detectors is sampled by two detectors with 60 time channels each. Per Channel Neutrons counted are used to compute the rate of decay. It is equivalent to measuring the rate at which thermal neu-trons are absorbed into the formation. The greater fluids and minerals capture thermal neutrons, the higher the value of sigma.

Pulse Decay Neutron Tool (PDN)

The PDN has been accepted by National Oil Companies like ADCO in Abu Dhabi and Kuwait Petroleum and is also established in the Gulf of Mexico. Even if the base log has been run by one of the big service companies, several examples show that the PDN can be used for time lapse logging. The instrument is a so called ‘Neutron – Gamma’ tool, i.e. It emits high energy neutrons (14 MeV) which interact with the surrounding nuclei, losing energy until they are captured. When the Neutrons are captured, the nucleus emits Gamma Rays, which are detected by the PDN relative to the time of the neutron burst. This is a measure for the thermal neutron capture cross section (E) and the tool provides real time Borehole Sigma and Formation Sigma readings.

The analysis of the measurements allow evaluation of the remaining saturation (Sor), identification of possible bypassed hydrocarbons, recognition of certain lithologies, and estimation of formation porosity. The PDN works in medium to high porosities and water salinities of 40,000 ppm and above.

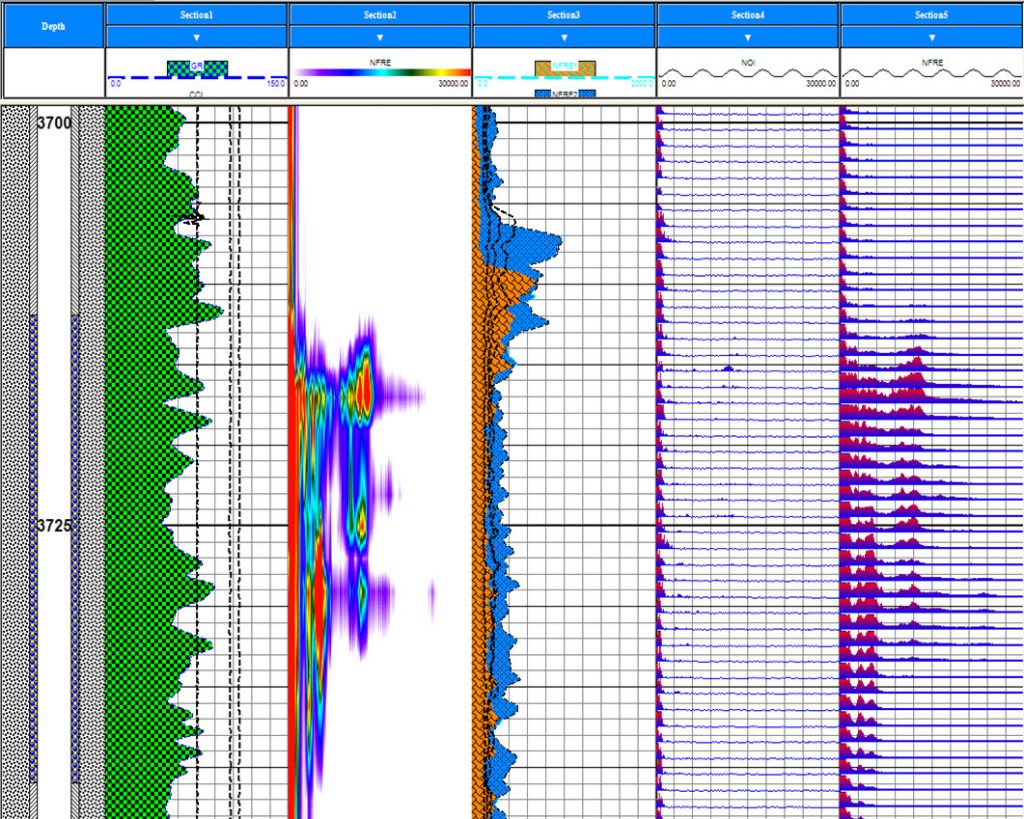

Cement Bond Tool

Cement bond tools measure the bond between casing and the cement placed in the annulus between the casing and the wellbore. Prestige utilizes both 8 and 16 sector bond tools which allows us to provide clients with tubings from 4″ to 22″ a proper cemented casing evaluation.The measurement is made by using acoustic sonic and ultrasonic tools.

The measurements of industry-standard sonic tools are usually displayed on a cement bond log (CBL) in millivolt units, decibel attenuation, or both. Reduction of the reading in millivolts or an increase in the decibel attenuation is an indication of better-quality bonding of the cement behind the casing to the casing wall.

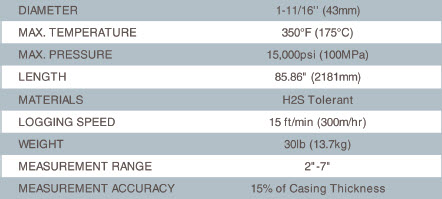

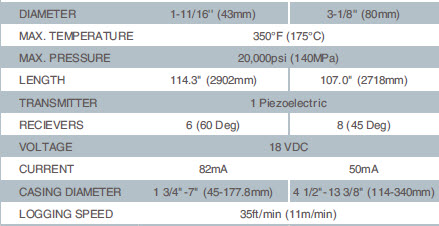

RBT

The RBT is equipped with one transmitter and two receivers constructed out of piezoelectric crystals. The near receiver, located 3ft from the transmitter, is constructed of an 8-sector radial sensor. The primary amplitude is constructed from radial signals at the near receiver while the Variable Density Log is constructed from the far receiver. The RBT can be deployed in deviated holes and combines easily with any of the other range of tools. The tool is compromised of H2S resistant materials throughout. All RBT tools have a built-in orientation sensor that allow for relative bearing and deviation data.

The analog waveform is completely digitized downhole and converted back to analog at surface for interpretation. By digitizing downhole the tool is able to:

- By-pass analog calibration pulse issues on H2S line transmission

- Store and revert to a calibrated configuration upon power up. Internal memory settings for sensor pickups circumvent the need for free pipe calibration

Applications

- Provide quantitative analysis of cement bond in eight 45 degrees segments for identification of channels in cement

- Identification of intervals of uniform bonding and detection of cement quality in casing sizes from 4 1/2 to 13 3/8 inch.

- Quantitative analysis of cement bond to casing

- Qualitative analysis of cement bond to formation

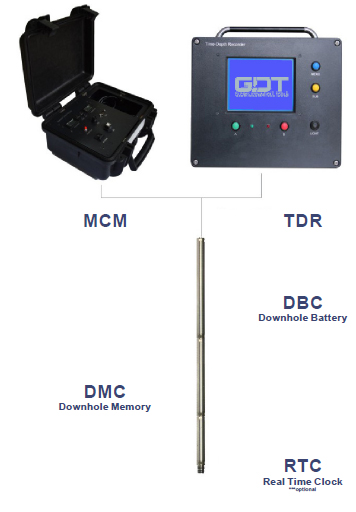

Memory System MLP

The Memory Logging System (MLP) is used when electric line conveyed realtime logging is not an available option, when using Slickline or when using Coiled , Tubing. A standard memory job consists of the following procedure: – DMC is synced and programmed through the MCM -TDR is connected to depth control device and records time versus depth -Tools are lowered into hole and preset procedure is executed on the DMC to record time versus sonde samples -Once back at surface, TDR and DMC data are merged in software to create a log

Conveyance:

- Slickline

- Coil Tubing

- Below standard wireline

- Extended reach tractor jobs

- Drill Pipe

Specifications

- PROTOCOL GDTbus

- DIAMETER 13/8″ (35mm) 111/16” (43mm) 27/8″

- MAX. TEMPERATURE 350°F (175°C)

- MAX. PRESSURE 15,000psi (103MPa)

- VOLTAGE 13.520 VDC

- CURRENT 1530mA

- STANDBY CURRENT 2mA

- SAMPLING RATE 20ms24hr, 20ms increment, adjustable

- DOWNLOAD RATE 4mb/min to cpu

- MEMORY CAPACITY 512mb (1GB custom) 500kbps

- COMMUNICATION RATE 500kbps

- BATTERY CAPACITY 6.2AH (Extended length available)

Spectral Noise Tool NST

The Spectral Noise Tool is used to detect the incoming noises in the wellbore generated at different spectral frequencies from different sources. By analyzing the frequency spectrum, the nature of fluids may be determined and leaks can be located.

Noise logging is applicable to oil/gas/water wells. It increases the success rate of locating leaks and channeling in tubulars. When combined with temperature and flowrate measurements, extensive quantitative interpretation can be performed.

Real time monitoring combined with the ability to save the audio to digital file provides better confidence in analysis.

Applications

- Location of production interval and productivity evaluation

- Fluid identification and flow rate evaluation

- Inspection of the channeling behind casing, leaks, backflows, sand production, and effect of packers